What Does Steel Road Plates Do?

Table of ContentsSteel Road Plates Fundamentals ExplainedSome Known Factual Statements About Steel Road Plates About Steel Road PlatesThe Single Strategy To Use For Steel Road PlatesSteel Road Plates Things To Know Before You Buy

When these big plates extend right into the lane of travel, there is a risk of puncturing to the tire wall surfaces - Steel road plates. Prone to changing in addition to adding to slides, journeys and falls the plates are challenging for a vehicle driver to see at a distance and specifically when presence is inadequate due to poor climateThe need to boost travelling and working conditions and the security of our streets is becoming increasingly crucial, with clear efficiency procedures presented by our States' Departments of Transport, and with direct responsibility for professionals. In a progressively litigious culture, obligations and penalties need to be managed proactively. Slides, journeys and falls and the resulting obligations and lawsuits expenses can deteriorate any type of revenue that a project may have produced and can also close a service down entirely.

In Australia and New Zealand, making use of steel plates to cover over energy trenches is a common technique and there are requirements in position for their usage; home plates should be safeguarded to the highway, there must be an anti-skid material externally, safety codes for operating machinery needs to be adhered to and the plate edges should be ramped with either chilly spot or other products so that the sides are chamfered to the existing street.

More About Steel Road Plates

You can see these new products released each day within safety and life vital applications such as utilities, building, industrial, freeway jobs and occasions all around the world. They are the products that quietly and quietly maintain all of us safe however we so hardly ever see them. The development of composite products has transpired largely in reaction to the requirement to boost tools usage and decrease costs whilst likewise guaranteeing website security and improving the photo of metropolitan workzones.

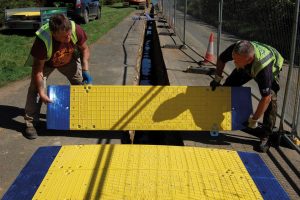

Quick and easy to release, composite road plates and trench covers decrease downtime as no hefty training tools is needed; a straightforward two-man lift minimizes what was once a significant job. Compound plates are, typically, one 3rd the weight of a steel alternative and can be installed in mins by two individuals when not in usage they can be stored quickly in a basic truck.

In the past, a trench would certainly be dug, covered with plywood and then wood sides would certainly be developed on site to create a single-use obstacle. This took some time, would certainly commonly lead to hold-ups in the job schedule, and incurred a price to produce the barrier. Making use of the composite solution, it can be laid down and the professional can leave knowing that the website is risk-free which the lower line has actually been improved.

Some Known Questions About Steel Road Plates.

There is no requirement to recess Roadway Plates, so reinstatement is dramatically less costly. Site security is improved as home plates have no inherent scrap value. Maintenance expenses disappear the irreversible anti-slip discover this surface and hi vis yellow composite material eliminate continuous maintenance costs associated with renewing anti-slip surfaces and painting timber and steel.

The task required trenching throughout driveways and cross streets in a household growth. Because Oxford's plates can be handled manually, we had the ability to run smaller sized machines. Integrating that with just how much quicker and safer Oxford plates are to set, we finished up with huge cost savings." Oxford Plastics has actually worked closely with utilities and professionals within the UK and US markets, creating the following generation of composite Roadway Plates.

Not known Details About Steel Road Plates

Popular with energy business dealing with gas, water, power and communication solutions, service providers are finding the Oxford products much simpler and more secure to lift into place than heavy steel plates and far more stable and durable than plywood. Moreover, there is a lowered cost of implementation say goodbye to products and work expenses connected with paint plywood.

Hand-operated handling is difficult with standard steel plates and big, costly crane training is called for all including to the expense and complexity of any kind of job. The ease of deployment and small size of the Road Plates were a best fit with the Keep London Moving campaign, where impact and rate of installation are crucial variables.

The costs and downtime related to the reapplication of the anti-slip covering to steel plates is prohibitive, due to really high wear rates. The Oxford 15/05 Compound Modular Road plates were created, originally, as a solution to the problems provided in the London effort. Given that, the Composite Modular Roadway Plate has located a discover this info here home in countries throughout the globe, with Oxford adjusting the variety to ensure compliance with the most rigorous security codes.

Get This Report on Steel Road Plates

The Civil Safety Products Plate has none of these issues as it is practically quiet through all processes from setup, throughout other worksite placement, and with to being taken apart. Civil Security Products' Roadway Plate is made from a number of components or internal areas that clip with each other and adapt to the bumps and angles of the road.